Protecting surgical instruments from corrosion; the importance of Passivation

Over the last few months we have received a number of calls from people to ask our advice on corrosion issues. The best advice we can give would be to ensure that any surgical instruments are only purchased via reputable companies. However, it is also useful to understand the processes which are involved in their manufacture. To protect surgical instruments from corrosion, it is essential that a documented passivation procedure is followed by the manufacturer. To find out more about how Platts & Nisbett surgical instruments are passivated, please read on…

What is passivation?

Passivation is the removal of iron compounds from the surface of the steel, by means of a chemical treatment. A Nitric Acid solution is used, which removes any surface contamination and forms a protective passive layer. The layer itself is very thin, typically 30 to 50 micron (µ) for stainless steel.

Why is passivation important?

It is essential that a protective passive layer is formed on the instrument during manufacture, to ensure the integrity of the metal does not become compromised. The presence of a well adhered passive layer will substantially increase the corrosion resistance of the steel, meaning that the instruments will last longer and be able to withstand regular cleaning and reprocessing. A porous or non-existent passive layer will dramatically lessen the lifetime of the product, and could cause rust to develop which may in turn contaminate other instruments in the tray.

How is passivation carried out?

Prior to passivation all surgical instruments are thoroughly cleaned and any mineral oils, polishes or organic substances are removed. Passivation is not a cleaning process and will not remove these substances from the surface of the material.

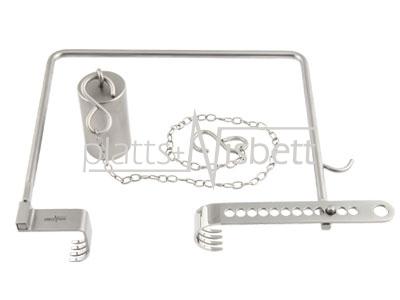

The surgical instruments are placed in baskets, and then loaded into a series of tanks. These tanks contain Nitric Acid, Water, and Copper Sulphate (which is used to corrosion test all our products). The three variables that must be controlled within the passivation process are time, temperature and concentration. To ensure the effectiveness of the process, daily checks are performed and the results are recorded.

When is passivation done?

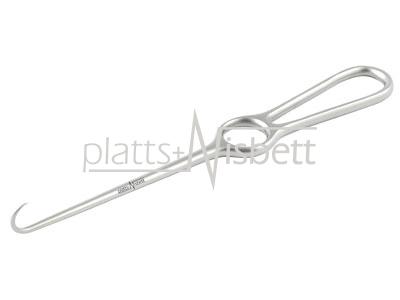

At Platts & Nisbett, passivation is done twice during the manufacturing process, both before and after laser marking. Many manufacturers only passivate once during manufacture, but we believe it needs to be done at these two stages to ensure it is fully effective. The laser marking process can have a detrimental effect on the the material, as it contaminates the surface by causing inconsistencies in the passive layer already formed. By passivating again after laser marking we can guarantee that the protective passive layer is left intact. All laser marked surgical instruments should be subjected to a subsequent clean and passivation process to remove surface contamination and promote corrosion resistance.

How can I be sure passivation has been effective?

As the protective passive layer is so thin, it cannot be seen by the naked eye. Corrosion testing is carried out on all our surgical instruments during the passivation process, which ensures they are fully corrosion protected when they leave our factory.

How do I maintain the passive layer on my surgical instruments, and ensure they stay corrosion free?

Always refer to manufacturer’s instructions / recommendations for cleaning and sterilising.

Ensure that instruments are cleaned as soon as possible after use, and do not overload baskets entering washer / disinfectors. It is essential that instruments are completely dried during the washer disinfector process, and that all soil / proteins are removed. Check all instruments for damaged areas which could cause corrosion or deem the instrument to be unsafe for use. Always isolate an instrument that shows sign of rust / corrosion, and never mix with other instruments as these will be contaminated.