CRAFTSMANSHIP

From the moment we opened our doors in 1977, the human touch has been vital to our Company’s ethos of unrivalled craftsmanship and performance. At our Sheffield factory, a team of highly skilled Surgical Instrument Makers endeavour to hand craft the finest Surgical Instruments available today.

Platts & Nisbett Craftsmen have spent a lifetime learning, practicing, and then teaching traditional techniques which take years to master. Our tradition of craftsmanship is unlike any other in this industry, and passing our skills on to the next generation is vital. We take pride in the Surgical instruments we produce by hand, and it is this exceptional attention to detail that makes a Platts & Nisbett Surgical Instrument instantly recognisable. The way it looks, the balance, the way it feels. In simple terms, its Quality.

People have often asked why our Surgical Instruments are not produced by machines. For example, the teeth on our Atraumatic Clamps are filed by hand, as a machine would tear the metal. They are so fine that once hand filed they have to be inspected using strong magnification lenses. Therefore, if you are wondering why we use people and not robots, the answer is that a machine would be unable to reproduce the techniques required. A machine would be unable to meet our exacting standards, a machine would not know how the instrument feels. We are proud to deliver our Quality through Craftsmanship.

CELEBRATING 40 YEARS OF UNRIVALLED CRAFTSMANSHIP

Over the last 40 Years, Platts & Nisbett Surgical Instruments have become synonymous with Quality.

You may ask, what is it that makes our products so different? Well, we can tell you.

Firstly we use only the highest quality raw materials; our Stainless Steel conforms with International Quality Standards, and is fully traceable.

Then it’s all the extra touches, the attention to detail, the hand craft we put in to each and every one. If we know it functions well, and it “feels right” then the surgeon will love it. Well made, well balanced Surgical Instruments are always so much appreciated in Operating Theatres.

Of course, being able to judge how the instrument feels is only something we know from our years of experience.

The “set” or tension of the instruments is so important, and perfecting this can only be done by time served Surgical Instrument Makers.

Looking at their hands, you can see they really are genuine, traditional Craftsmen. Every line, every crease, every callus has the story of a Surgical Instrument behind it. How many Surgical Instrument Companies can show you this?

Here are some examples of the hand crafted skills involved in the manufacture of our Surgical Instruments.

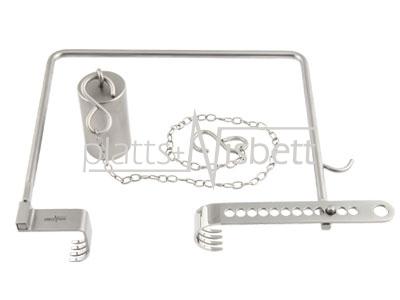

RETRACTOR RACK & TRIGGER MECHANISMS

All Platts & Nisbett Self Retaining Retractors are rigorously tested throughout manufacture and prior to despatch. Each rack and trigger are individually filed by hand, ensuring that the correct radius is achieved. This ensures smooth operation of the instrument, and guarantees that the retractor will not slip during use.

© Platts & Nisbett

© Platts & Nisbett

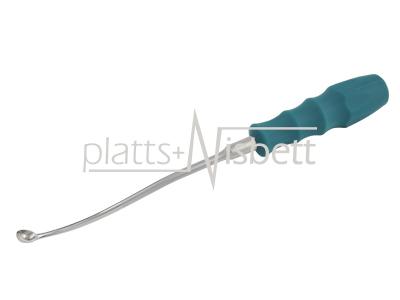

RETRACTOR TEETH

Teeth are bent by hand using special tooling which we also manufacture. We ensure that the teeth intermesh correctly, so the Retractor can be opened and closed with ease. Perfectly formed teeth mean that the incision can be opened in a safe and controlled way during surgery.

© Platts & Nisbett

© Platts & Nisbett

© Platts & Nisbett

© Platts & Nisbett

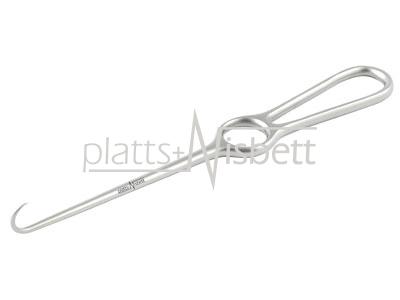

HAND FILING OF LUCS NASAL FORCEP HEART SHAPE

The delicate hand filing of a Surgical Instrument is a skill which takes many years to master. We are the last remaining UK Manufacturer of the Lucs Forcep, and when you see the intricate filing technique used to create the Heart Shape, it is easy to see why. This is only done by expert Craftsmen with years of experience at Platts & Nisbett.